Taking full advantage of Effectiveness: The Value of Genuine Komatsu Undercarriage Parts

Taking full advantage of Effectiveness: The Value of Genuine Komatsu Undercarriage Parts

Blog Article

Explore Undercarriage Components for Your Equipment Needs

Comprehending the parts that make up the undercarriage and the relevance of picking the ideal components is vital to ensuring smooth procedures and cost-effective maintenance. As we discover the world of undercarriage components for machinery needs, a deeper understanding into the ins and outs of this crucial system will unfold, dropping light on the foundation that sustains the performance of your equipment.

Significance of Undercarriage Upkeep

Regular maintenance of undercarriage parts is vital for guaranteeing ideal efficiency and long life of machinery. The undercarriage of hefty devices, such as excavators, bulldozers, and track loaders, plays an essential function in supporting the weight of the maker, supplying stability on numerous terrains, and enabling smooth operation - komatsu undercarriage parts. Overlooking undercarriage upkeep can cause costly repair work, lowered efficiency, and possible security hazards

Routine examinations of undercarriage components, such as track chains, gears, rollers, and idlers, are necessary to recognize wear and tear early on. Resolving problems immediately can protect against further damages to the undercarriage and various other components of the equipment. Proper cleaning of undercarriage elements is likewise needed to get rid of dirt, debris, and other contaminants that can increase wear and deterioration.

Regular lubrication of undercarriage components is another essential facet of upkeep to make sure smooth motion and reduce friction between components. In addition, tracking the usage hours and keeping upkeep records can help in scheduling prompt substitutes and extending the overall life-span of the machinery. By focusing on undercarriage maintenance, devices proprietors can take full advantage of effectiveness, minimize downtime, and eventually save money on repair prices in the future.

Kinds Of Undercarriage Parts

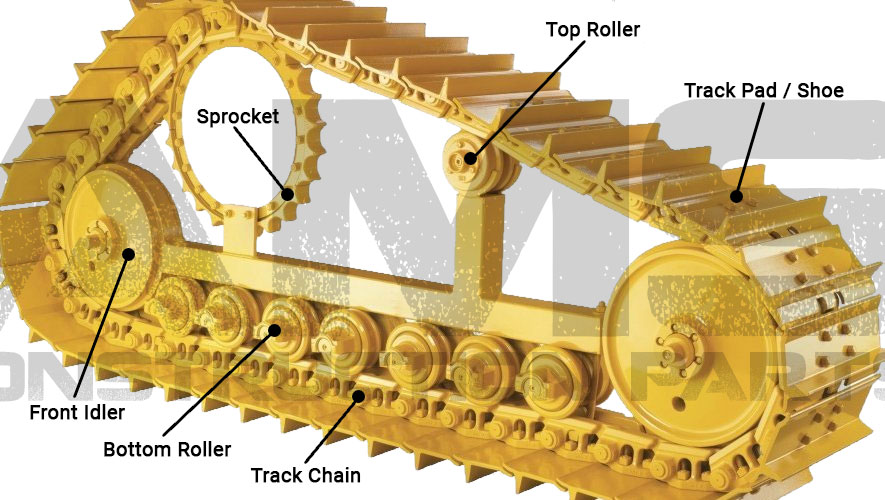

Upkeep of undercarriage components is necessary for machinery durability; understanding the different kinds of undercarriage parts is important for efficient maintenance techniques. Undercarriage components differ depending on the kind of machinery and its designated use. Common sorts of undercarriage components consist of track chains, track footwear, rollers, idlers, sprockets, and track frameworks.

Track chains are liable for thrusting the machinery forward and sustaining the weight of the equipment. Track shoes provide traction and secure the track chain from damage. Rollers aid in weight circulation and track assistance, while idlers aid maintain proper track tension. Gears engage with the track chain and transfer power to move the machinery. Ultimately, track frames offer as the structure for the whole undercarriage assembly, attaching all the elements with each other.

Normal inspection and upkeep of these undercarriage components are necessary to stop pricey repair services and downtime. By recognizing the function of each type of undercarriage component, equipment operators can make sure ideal performance and prolong the life-span of their equipment.

Factors to Consider When Picking Components

Another vital element is compatibility with the details equipment design. Each item of equipment might have one-of-a-kind requirements see this site for undercarriage parts, including size, design, and specs. Guaranteeing that the components are suitable with the equipment will certainly aid prevent operational problems and premature wear.

Additionally, it is important to consider the operating problems in which the equipment will certainly be used. Elements such as surface, weather condition conditions, and usage regularity can all affect the deterioration on undercarriage components. Picking parts that are made to withstand the details operating problems can assist extend the life of the machinery and lower maintenance costs in the future.

Advantages of High-Quality Undercarriage Components

High-grade undercarriage parts play a vital role in enhancing machinery performance and expanding its operational longevity. By buying first-class undercarriage parts, equipment drivers take advantage of increased durability and integrity. One of the key advantages of using premium undercarriage components is enhanced effectiveness. These components are developed to endure heavy loads, extreme terrains, and requiring functioning conditions, guaranteeing that the equipment operates at its ideal degree without regular malfunctions or breakdowns.

In addition, premium undercarriage parts contribute to set you back savings over time. While the preliminary financial investment may be higher compared to common components, the toughness Read Full Article and long life of costs components decrease the demand for constant replacements and fixings. This not just minimizes downtime yet additionally reduces upkeep costs, eventually leading to higher total productivity and earnings for companies that rely upon hefty equipment.

Furthermore, superior undercarriage parts improve safety by decreasing the threat of unexpected failures or mishaps. The increased security and efficiency provided by premium parts create a safer working environment for equipment operators and those operating in close proximity to the devices. Inevitably, selecting high-quality undercarriage components is a calculated choice that yields various advantages in regards to performance, cost-efficiency, long life, and safety.

Tips for Extending Undercarriage Lifespan

To make best use of the long life of undercarriage parts for equipment, implementing proactive care methods is crucial for guaranteeing optimum efficiency and resilience. Over-tightened tracks can lead to raised tension on the undercarriage, while helpful site loose tracks can cause imbalance and unequal wear.

Operating the equipment within suggested standards, such as avoiding extreme rates or overloading, can additionally add to prolonging the undercarriage life-span. By adhering to these pointers, machinery owners can ensure ideal efficiency and sturdiness of their undercarriage components.

Verdict

In final thought, keeping the undercarriage parts of machinery is crucial for optimal performance and longevity. Spending in premium undercarriage parts not just enhances efficiency yet likewise reduces downtime and pricey repairs.

Routine upkeep of undercarriage components is important for making certain optimum efficiency and durability of machinery.Upkeep of undercarriage parts is essential for machinery durability; comprehending the different kinds of undercarriage components is crucial for reliable maintenance practices.When picking undercarriage components for equipment, it is essential to consider various factors to ensure optimum performance and longevity.To make the most of the longevity of undercarriage components for equipment, carrying out proactive treatment practices is essential for making certain optimal performance and sturdiness. By following these suggestions, equipment owners can make sure optimum efficiency and durability of their undercarriage parts.

Report this page